Aussie researchers have brewed up a new path towards boosting construction sustainability that could soon be pouring all around the globe.

Sidewalks made from used coffee could become a refreshing game-changer for the concrete production process, helping to filter through the industry’s overflowing carbon footprint.

Australians throw away 75 million kilograms of used ground coffee every year – finding their way to landfills alongside the nation’s organic waste to boil up three per cent of the nation’s total greenhouse gas emissions.

Meanwhile, cement currently accounts for 8 per cent of global emissions alone due to the chemical process requirements behind its production.

But, researchers have found the dense notes of spent coffee can make for a robust cementitious material substitute, replacing the sand that makes up 28 per cent of the building material.

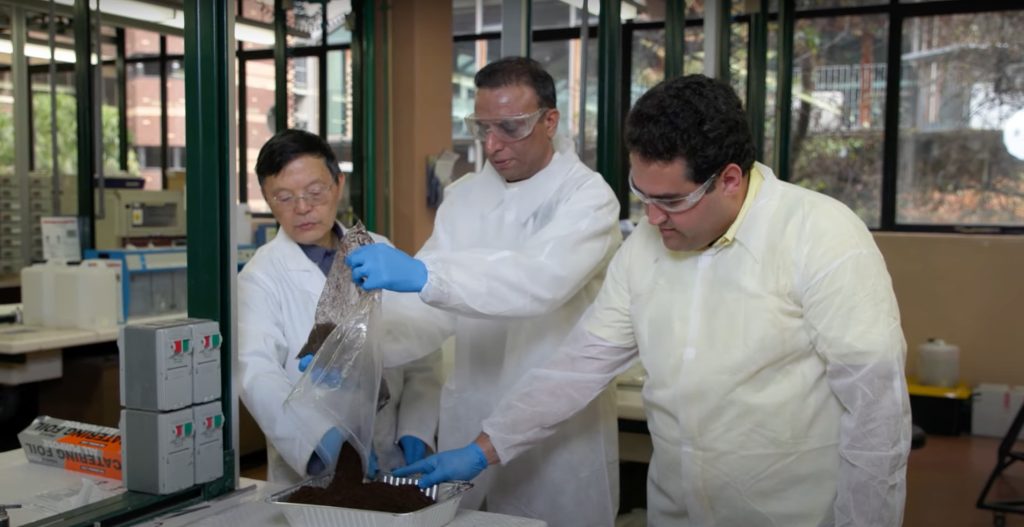

Scientists from RMIT University and Australian-owned civil infrastructure firm Bildgroup have paired up better than cake and espresso to trial the ‘ground’ breaking find in a number of circular economy footpath projects across Victoria.

How to brew the perfect coffee footpath:

The process involves transforming the grounds into coffee biochar by putting them through a low-energy process without oxygen at 350 degrees Celsius. The researchers are trialling the same process with other organic waste, such as wood chips, which can make for a more robust cup of concrete.

RMIT lead researcher Dr Rajeev Roychand says the new production method could reduce the embodied carbon emissions of most construction projects by replacing up to 15 per cent of the sand they use.

“It’s very exciting to see this world-first trial of our coffee and wood-based biochar in these footpaths in collaboration with Macedon Ranges Shire Council,” he said.

“We are currently working in the supply chain sector to make this research into a mainstream product for commercial applications, and we’re not only looking into coffee – we’re expanding this into all forms of different organic waste.”

Residents of Gisborne in Central Victoria will be the first to get a taste of walking on the new paths, but despite their unique construction notes, it is unlikely they will notice anything different.

“We’re taking those experiments and putting them in the ground and the field today. We’re going to have people walking across the concrete that includes these products, and RMIT is going to be coming back and doing testing to see how they stand up,” Director of Assets and Operations at Macedon Ranges Council Shane Walden said.

Even though we’re using coffee grounds or mulch, residents aren’t going to see or smell any difference in this concrete product.”

Director of Assets and Operations at Macedon Ranges Council – Shane Walden.

However, not only will carbon emissions and landfills be reduced should concrete footpaths catch on, but also spoonfuls of potential savings for construction companies and concreters whose projects will subsequently use less cement.

“Our research creates a potential even to reduce the required cement content. Since we are achieving a 30% increase in strength for the coffee concrete, this could reduce the required cement content by as much as 10%, based on our previous experience,” Dr Roychand said.