Engineers in Australia have found a new way to make power-pole insulators resistant to fire and electrical sparking, promising to prevent dangerous pole-top fires and reduce blackouts.

Pole-top fires pose significant challenges to power providers and communities worldwide. In March, pole-top fires cut power from 40,000 homes and businesses in Perth.

The 2020 Royal Commission into National Natural Disaster Arrangements found that power outages experienced by 280,000 customers from various energy providers during Black Summer fires were mainly triggered by events involving insulators and poles.

RMIT University Vice-Chancellor’s Postdoctoral Fellow Dr Tariq Nazir said these fires can occur when consecutive hot, dry and windy days are followed by damp and misty conditions.

“Dust and pollution builds up on power-line insulators, which enables electricity to spark and heat metal fixtures that can cause wooden power poles to catch fire,” he said.

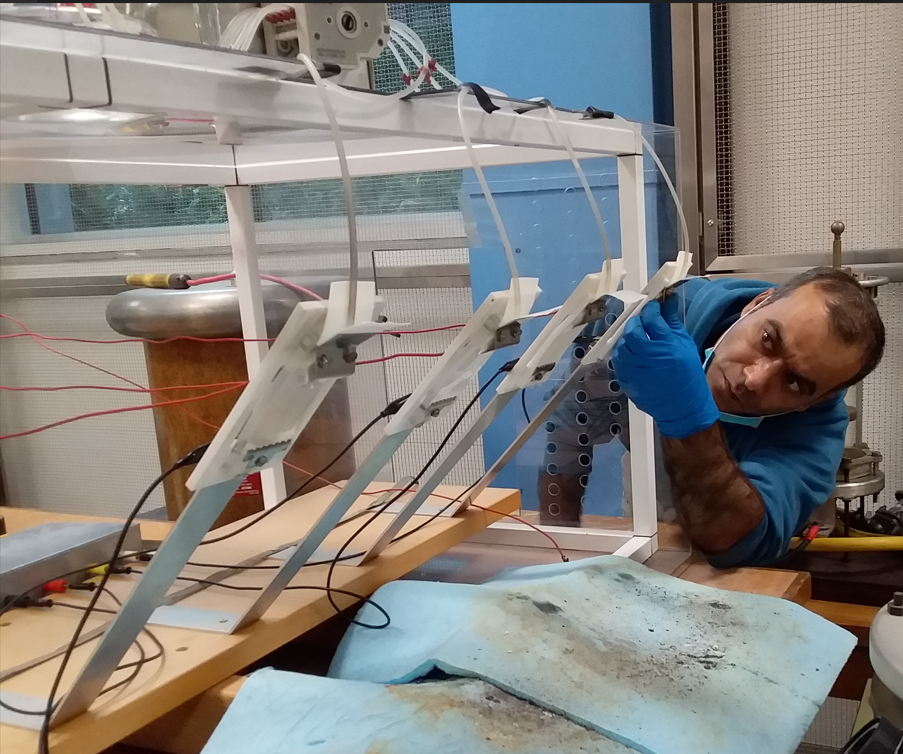

In collaboration with researchers at the University of New South Wales, Nazir has improved the performance and safety of insulation materials for power poles at the lab scale. Their results and analysis are published in the high-impact international journal Advanced Composites and Hybrid Materials.

“Power utilities wash insulators on overhead power lines as a vital maintenance procedure to prevent problems like contamination and electrical sparking, which can cause pole-top fires and power outages,” said Nazir from RMIT’s School of Engineering.

“Our proposed silicone rubber composite material offers a potential solution that could save power companies time, maintenance resources and ultimately money from prevent damage to their assets.”

The composite material comprises chopped fiberglass, aluminium hydroxide and a type of clay derived from volcanic ash as additives.

“Our innovation could serve as a protective coating or paint for ceramic and glass insulators, providing extra defence against environmental factors such as moisture, pollution and fire,” Nazir said.

“We are keen to engage with fire-retardant coating manufacturers, electrical utilities, electrical insulation designers, manufacturers of electrical insulation products and regulatory agencies to further develop and prototype this work.”

New insulating material in pole position

Nazir said their research’s novelty was in exploring the flame retardancy of insulator materials.

“Others are working mainly in electrical discharge resistance of material,” he said.

“I am trying to achieve both sides, whilst maintaining the required electrical insulation level of composites.”

With the help of prospective partners, the team will aim to transition to larger-scale production processes for commercial applications and conduct more comprehensive durability testing under simulated outdoor conditions.

“Application-specific testing will assess suitability for various scenarios, and integration with existing systems will be explored,” Nazir said.

Research team fires up bushfire safety progress

Nazir and his colleagues are behind another fire-protection innovation, a fire-retardant paint that is already commercially available in Australia.

As revealed by Build-it late last year, engineers from UNSW Sydney in conjunction with those from RMIT, worked alongside experts from Flame Security International to develop FSA Firecoat, a fire-resistant paint that can reduce and prevent fire from spreading across properties.

The team spent nearly five years perfecting the formula, which became the first to pass stringent bushfire simulation Australian standard testing before reaching Bunnings’ shelves nationwide.

The carefully crafted chemicals within the coating see it swell upon heat contact, forming a layer of insulating protective char that expands as a protective barrier between the fire and the building it’s on.

Achieving the ‘Bushfire Attack Level 40’ rating, the paint is indicated to withstand higher levels of radiant heat measuring up to 50kW/m² and is ember resistant.

Director of the ARC Training Centre for Fire Retardant Materials and Safety Technologies at UNSW Sydney, Professor Guan Yeoh, says the paint could save hundreds of homes from extreme fire conditions.

“If a building is not protected in any way and it starts to burn, then it can become a source of heat for the fire to continue, like a chain reaction,” he said.

Home improvement and hardware retail giant Bunnings secured an initial order of 80,000 litres of the paint after being stunned by its breakthrough tech.

Bunnings managing director Mike Schneider told Build-it the paint would become a game changer just in time for bushfire season.

“It’s never been more important to find new ways to protect the built environment and ensure our communities remain resilient,” he told Build-it.

“We have no doubt this amazing product will become a key feature in asset protection, management and future construction standards.”